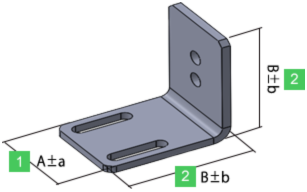

| No. | 规格部位 | 基准尺寸 | 板厚 | 规格值 | 部位示例 | ||

| 大于 | 至 | 大于 | 至 | ||||

| 1 | 无折弯部 | 0.5 | 3 | – | 1 | ±0.10 |  |

| 1 | 3 | ±0.20 | |||||

| 3 | 6 | – | 1 | ±0.15 | |||

| 1 | 4 | ±0.30 | |||||

| 4 | – | ±0.40 | |||||

| 6 | 30 | – | 1 | ±0.20 | |||

| 1 | 4 | ±0.40 | |||||

| 4 | – | ±0.60 | |||||

| 30 | 120 | – | 1 | ±0.30 | |||

| 1 | 4 | ±0.55 | |||||

| 4 | – | ±0.80 | |||||

| 120 | 400 | – | 1 | ±0.35 | |||

| 1 | 4 | ±0.70 | |||||

| 4 | – | ±1.05 | |||||

| 400 | 1000 | – | 1 | ±0.50 | |||

| 1 | 4 | ±1.00 | |||||

| 4 | – | ±1.45 | |||||

| 1000 | 2000 | – | 1 | ±0.65 | |||

| 1 | 4 | ±1.30 | |||||

| 4 | – | ±2.00 | |||||

| 2 | 折弯加工部 | 0.5 | 3 | – | 1 | ±0.20 | |

| 1 | 4 | ±0.45 | |||||

| 3 | 6 | – | 1 | ±0.30 | |||

| 1 | 4 | ±0.60 | |||||

| 4 | – | ±0.90 | |||||

| 6 | 30 | – | 1 | ±0.40 | |||

| 1 | 4 | ±0.80 | |||||

| 4 | – | ±1.30 | |||||

| 30 | 120 | – | 1 | ±0.50 | |||

| 1 | 4 | ±1.00 | |||||

| 4 | – | ±1.60 | |||||

| 120 | 400 | – | 1 | ±0.70 | |||

| 1 | 4 | ±1.40 | |||||

| 4 | – | ±2.00 | |||||

| 400 | 1000 | – | 1 | ±0.90 | |||

| 1 | 4 | ±1.70 | |||||

| 4 | – | ±2.80 | |||||

| 1000 | 2000 | – | 1 | ±1.30 | |||

| 1 | 4 | ±2.20 | |||||

| 4 | – | ±3.20 | |||||

※ GB/T 15055—2007冲压件未注公差尺寸极限偏差的公差等级:采用m级

※ 指定喷涂时,为坯料状态下的规格值

适用容许尺寸公差的部位仅限同一面上的孔之间和因折弯而相邻的端面、垂直面之间的尺寸。

不相邻面上(跨越多个折弯加工部)的孔之间、孔与端面的尺寸不适用容许尺寸公差。(参照以下例1、例2)

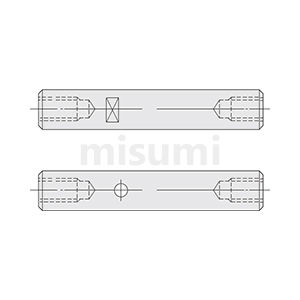

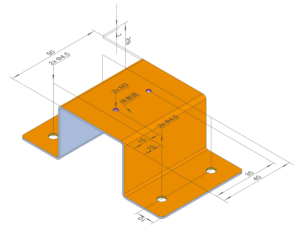

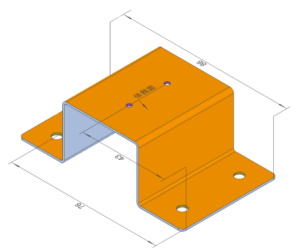

| 例1) 适用容许尺寸公差的尺寸 | 例2) 不适用容许尺寸公差的尺寸 |

|  |